AGF-SPV3 AGFRC USB Servo Programmer for AGFRC Programmable servo

Couldn't load pickup availability

AGFRC AGF-SPV3 USB program card used for AGFRC servo with ASS icon mark. Easy to use and DIY the parameter of the AGFRC servo. AGF-SP V3 is an upgraded version of the AGF-SP V2, it can use for our 1/5 large scale servo A280BHMW /A280BVSW, 4S high voltage servo A86BUMW , as well as helicopter servo A80BHM-H /A80BHN-H /A80BHX-H /A80BHP-H. What's more, all of our programmable servo with ASS icon mark, can click the "Narrow Band" function to be used as the Tail Servo.

NOTE: This program card only ideal for AGFRC servo with ASS icon mark! AGFRC servo without ASS icon mark, and other brands of servo are not applicable

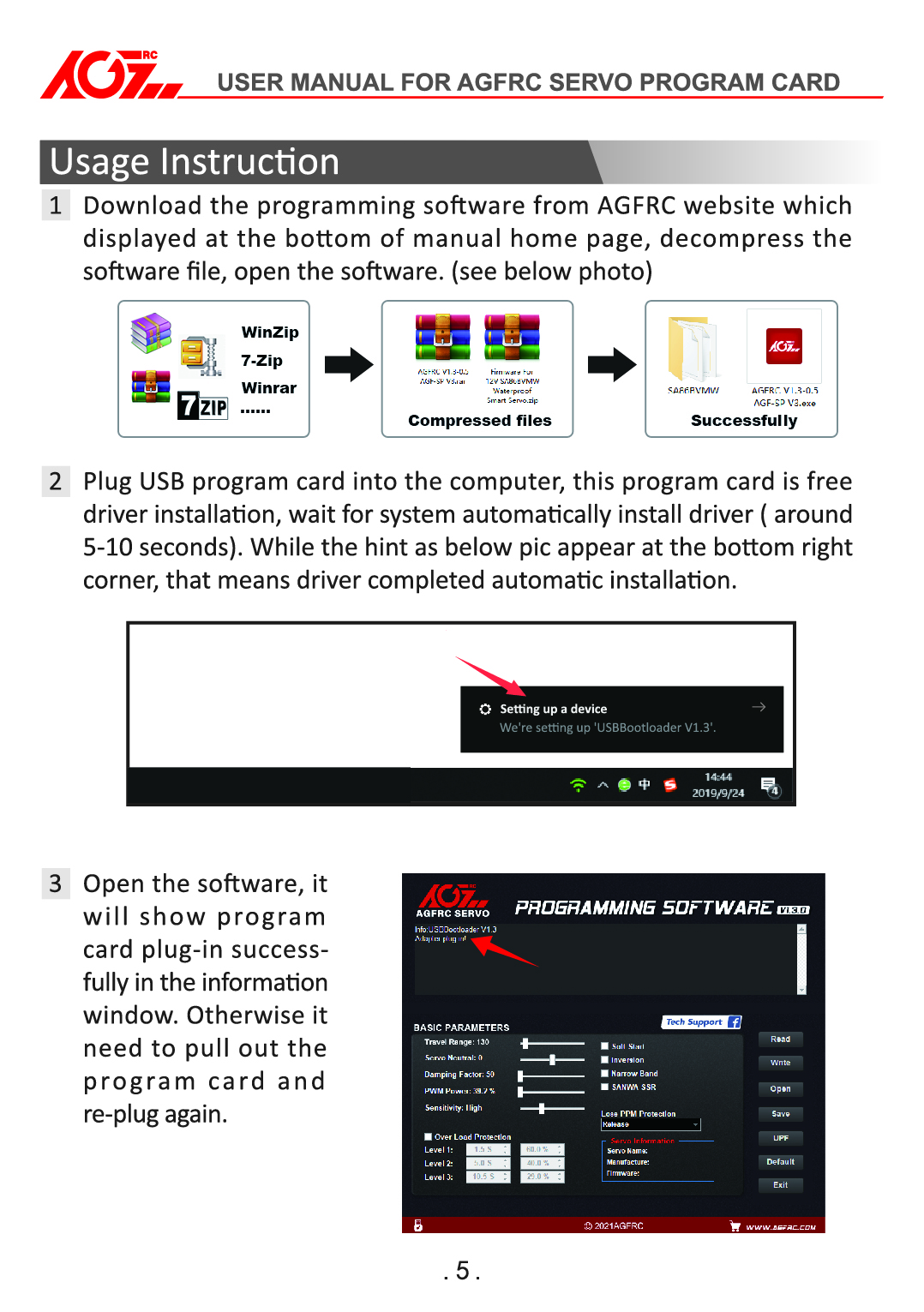

Software download address of AGF-SPV3 USB programming card : Click here

System Requirement

1. Operating Voltage: USB(5V/500mA).

2. Operating System: Windows XP/Windows Vista/Windows 7/Windows 8 /windows10 ( 32/64bit).

3. Application: AGFrc Programmable Servos with ASS icon marked.

-

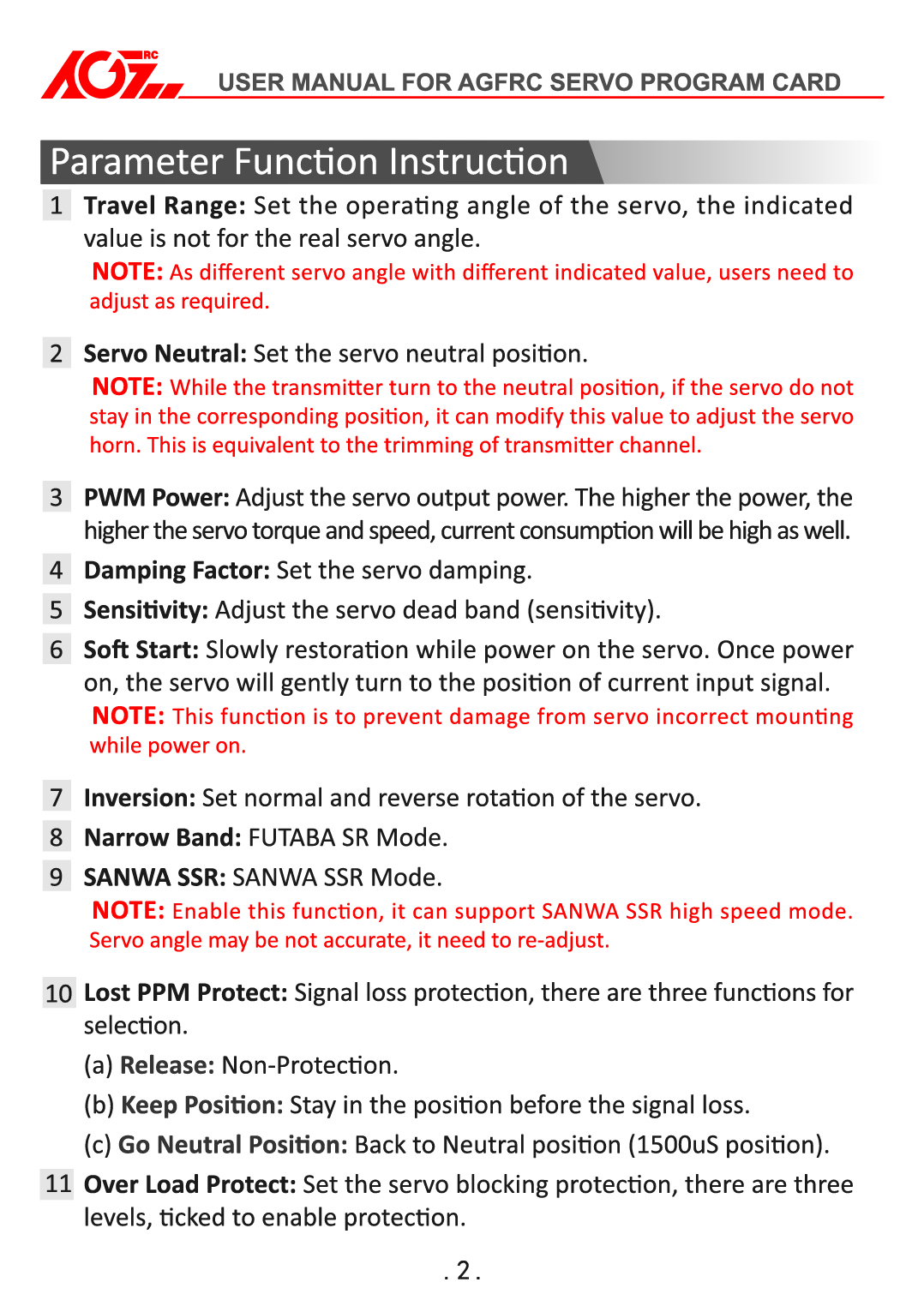

Parameter Function Instruction

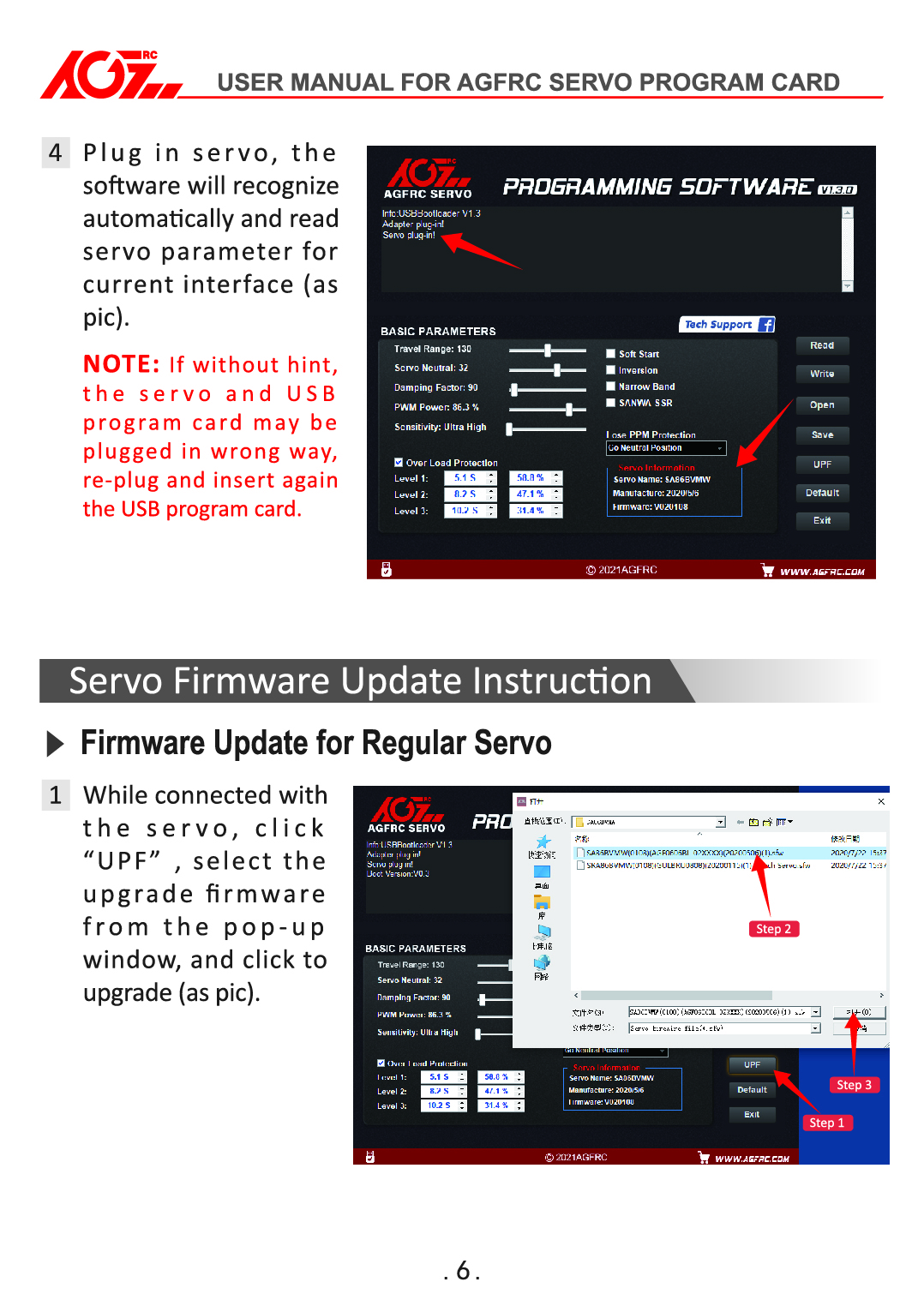

1. Servo Angle: Set the servo rotation angle

2. Servo Neutral: Set the servo neutral position

Note: While the transmitter turn to the neutral position, if the servo do not stay in the corresponding position, it can modify this value to adjust the servo horn. This is equivalent to the trimming of transmitter channel.

3. PWM Power: Adjust the servo output power. The higher the power, the higher the servo torque and speed, current consumption will be high as well.

4. Damping Factor: Set the servo damping.

5. Sensitivity: Adjust the servo dead band (sensitivity).

6. Soft Start: Slowly restoration while power on the servo. Once power on, the servo will gently turn to the position of current input signal.

Note: This function is to prevent damage from servo incorrect mounting while power on.

7. Inversion: Set normal and reverse rotation of the servo.

8. Narrow Band: FUTABA SR Mode

9. SANWA SSR: SANWA SSR Mode

Note: Enable this function, it can support SANWA SSR high speed mode. Servo angle may be not accurate, it need to re-adjust.

10. Lost PPM Protect: Signal loss protection, there are three functions for selection,

a. Release: Non-Protection

b. Keep Position: Stay in the position before the signal loss

c. Go Neutral Position: Back to Neutral position (1500uS position)

11. Over Load Protect: Set the servo blocking protection, there are three levels, ticked to enable protection.

Level 1: Set the starting time and power value of the primary protection.

Level 2: Set the starting time and power value of the secondary protection.

Level 3: Set the starting time and power value of the tertiary protection.

Note: Left side is to set the protection starting time, right side is to set output power value after

enable starting protection.

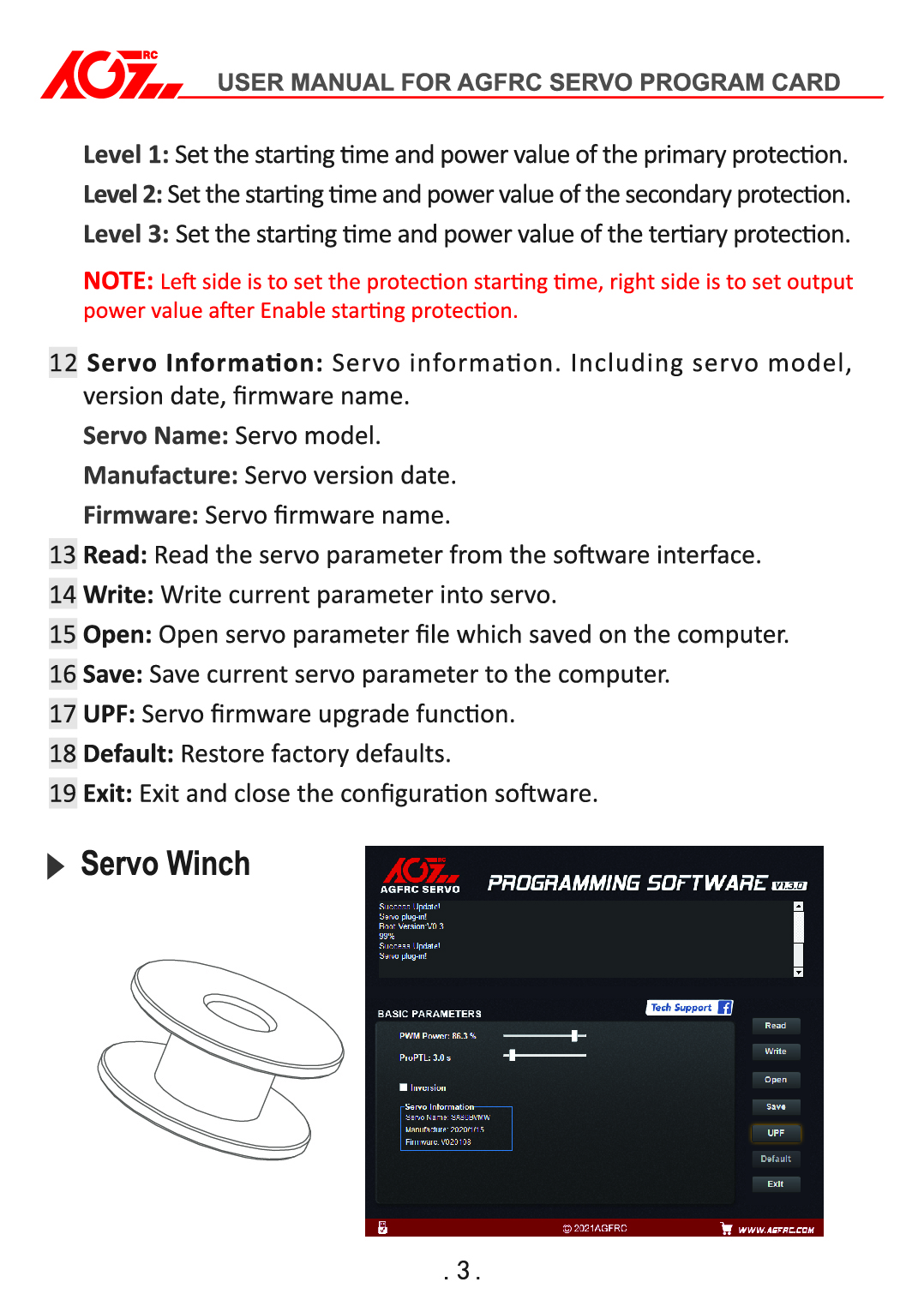

12. Servo Information: Servo information. Including servo model, version date, firmware name.

Servo Name: Servo model

Manufacture: Servo version date

Firmware: Servo firmware name

13. Read: Read the servo parameter from the software interface.

14. Write: Write current parameter into servo.

15. Open: Open servo parameter file which saved on the computer.

16. Save: Save current servo parameter to the computer

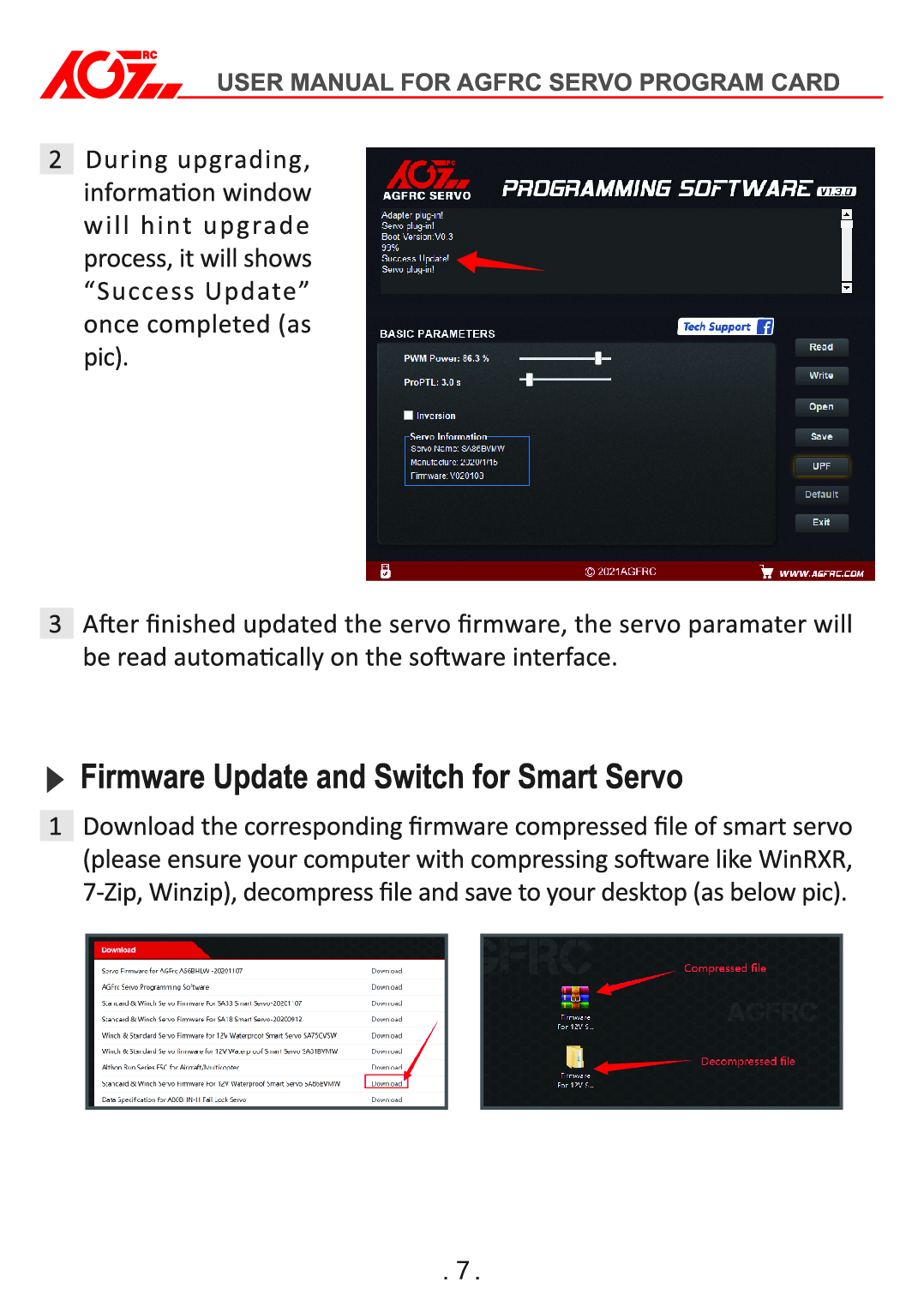

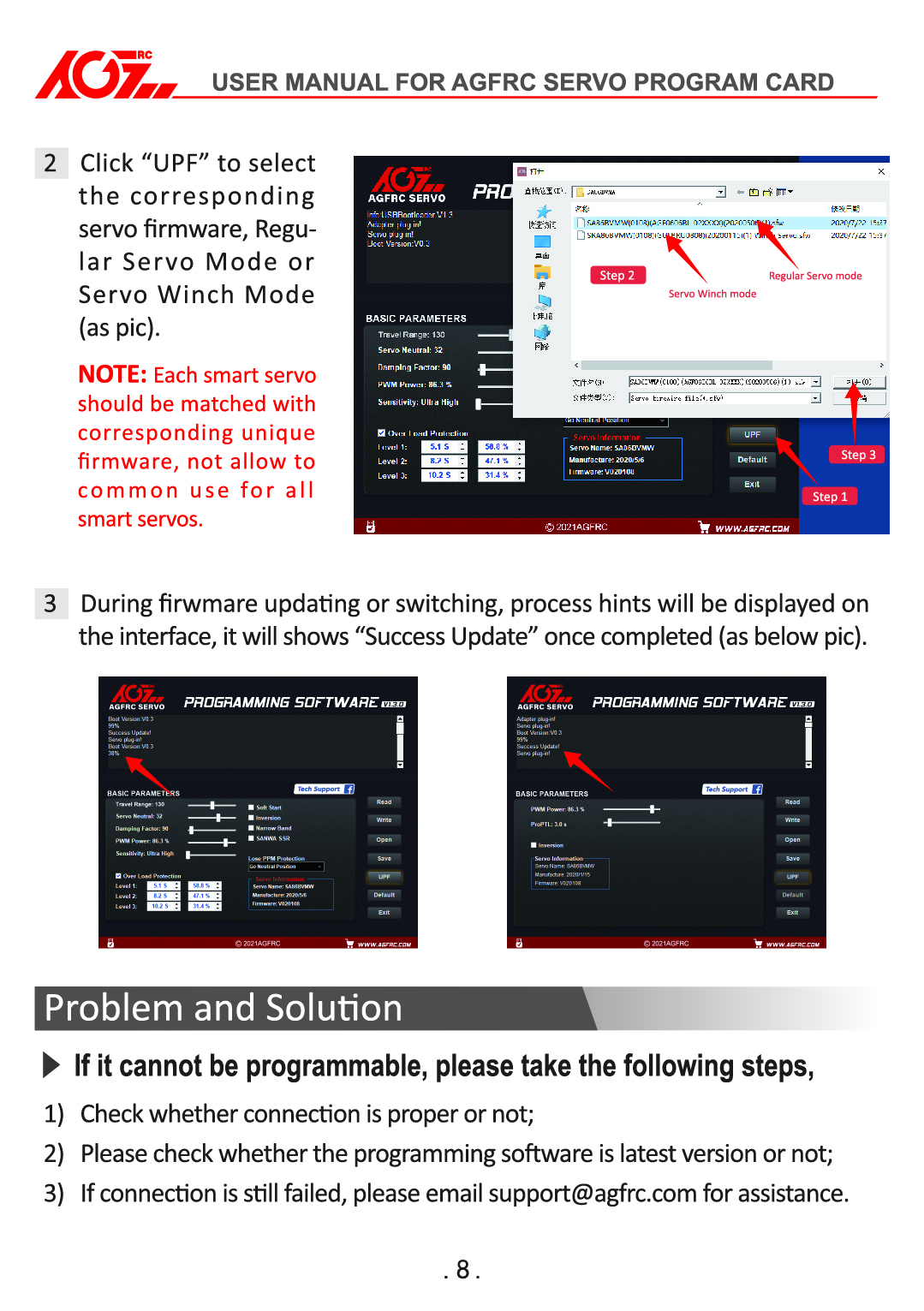

17. UPF: Servo firmware upgrade function.

18. Default: Restore factory defaults.

19. Exit: Exit and close the configuration software

Parameter Function Instruction

1. PWM Power: Adjust the servo output power. The higher the power, the higher the servo torque and speed, current consumption will be high as well.

2. ProPTL:3.0s: The starting time for servo blocking protection (unit: seconds), while the servo is blocked and last up to the setting value, the protection will be active, and servo will stop working.

3. Inversion: Set normal and reverse rotation of the servo

4. Servo Information: Servo information. Including servo model, version date, firmware name.

Servo Name: Servo model

Manufacture: Servo version date

Firmware: Servo firmware name

5. Read: Read the servo parameter from the software interface.

6. Write: Write current parameter into servo.

7. Open: Open servo parameter file which saved on the computer.

8. Save: Save current servo parameter to the computer.

9. UPF: Servo firmware upgrade function.

10. Default: Restore factory defaults.

11. Exit: Exit and close the configuration software.

Problem and Solution

If it cannot be programmable, how to inspect,

1) Check whether connection is proper or not;

2) Please check whether the programming software is latest version or not;

3) If connection is still failed, please email "support@agfrc.com" for assistance.